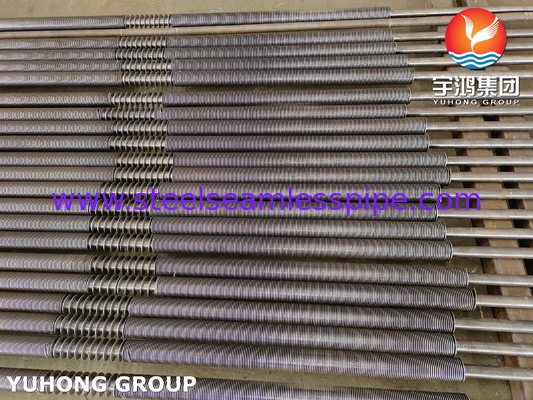

ASTM A106 Gr.B Acero al carbono U Bend HFW Tubos de aleta sólida para economizadores de gases de escape de motores diesel

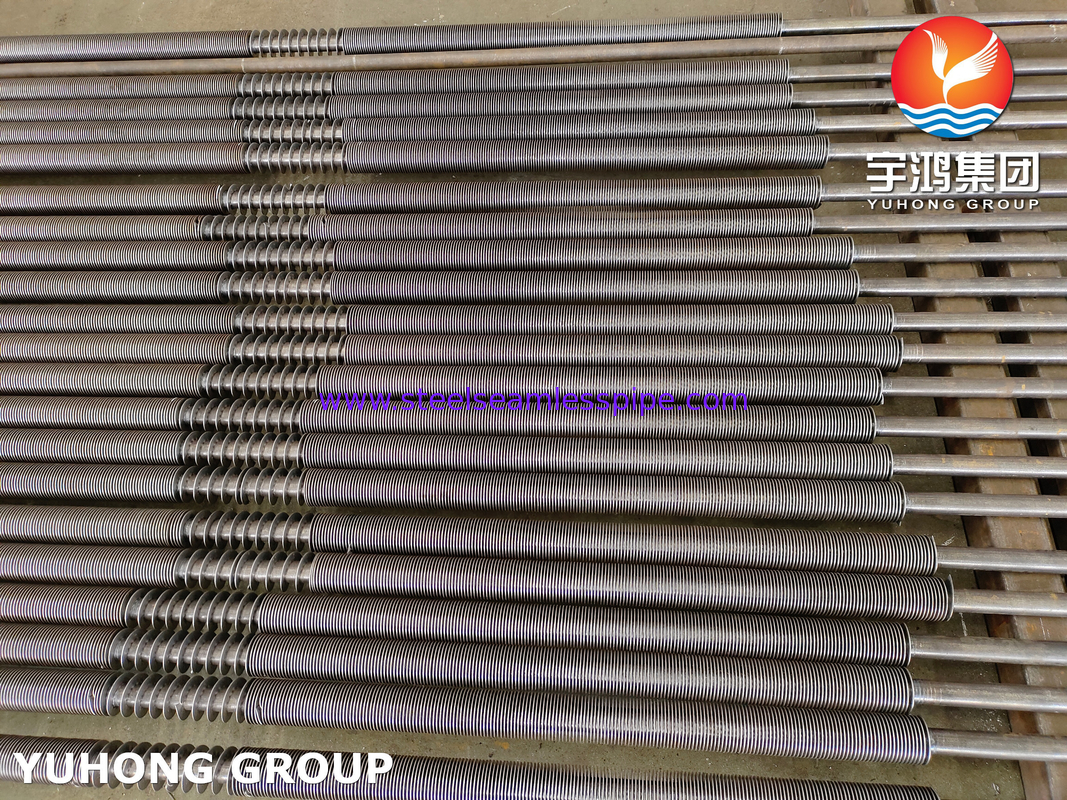

Los tubos con aletas U de acero al carbono A106 Gr.B son elementos de transferencia de calor altamente eficientes.Las aletas externas se unen helicoidalmente al tubo base para aumentar significativamente su superficie externaLa corriente de alta frecuencia genera efectos de piel y proximidad, generando instantáneamente un alto calor en los puntos de contacto entre el tubo base y el material de las aletas.causando que se derritan y se fusionen bajo presión.

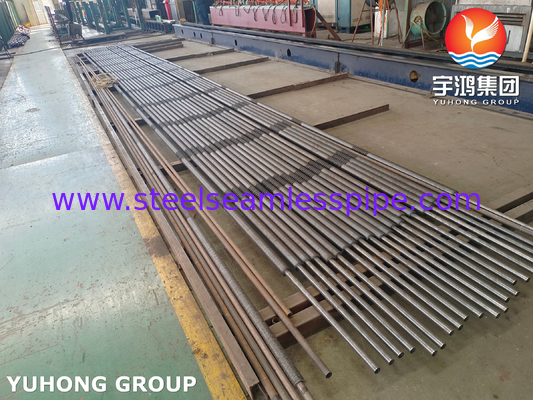

Los tubos con aletas se doblan en forma de "U".

ASME SA / ASTM A106 GR.B Tubos y tuberías sin costuras de acero al carbono Composición química:

| Composición química (%) |

| Grado |

C (máximo) |

En |

Si (min) |

Cu ((Max) |

Ni ((Max) |

Cr (max) |

Mo (max) |

V (máximo) |

P (max) |

S (máximo) |

| B. El trabajo |

0.3 |

0.29 ~ 1.06 |

0.1 |

0.4 |

0.4 |

0.4 |

0.15 |

0.08 |

0.035 |

0.035 |

A 106 Clase B SMLS Tubos y tuberías Propiedades mecánicas:

| Propiedades mecánicas: |

| Grado |

La resistencia a la tracción (Mpa), min. |

La fuerza de rendimiento (Mpa), min. |

| B. El trabajo |

415 |

240 |

El suelo

Proceso: la cinta de acero se introduce en la máquina de soldadura de alta frecuencia en un estado suave.la raíz lisa de la tira se derrite y soldas a la superficie del tubo base al instante.

Ventajas:

El proceso es maduro, eficiente, y la corriente principal en el mercado.

La conductividad térmica óptima se logra porque la zona de soldadura es continua y completa.

Adecuado para tubos de base de diversas especificaciones, incluidos los tubos de paredes delgadas.

Con dientes

Perforación: se perforan las serraduras uniformes en la raíz de la franja de la aleta.

Rincón: se preenrollan ranuras espirales poco profundas en la superficie del tubo base.

Inserción y soldadura: La banda de aleta dentada se envuelve y presiona en las ranuras, haciendo que los dientes se deformen plásticamente y se incrusten en el tubo base.La soldadura se produce no sólo en la raíz de la aleta, pero también en los huecos entre los dientes y la trompa base.

Ventajas:

Incluso si hay pequeñas áreas de soldadura incompleta, los dientes mecánicamente entrelazados proporcionan una fuerte resistencia a la extracción, lo que reduce significativamente el riesgo de fallo general.

Excelente resistencia a la fatiga: la estructura mecánicamente entrelazada resiste eficazmente las tensiones térmicas alternas causadas por arranques y paradas frecuentes y fluctuaciones repentinas de temperatura,prevención de grietas inducidas por la fatiga en las raíces de las aletas.

Aplicación

Generadores de vapor de recuperación de calor (HRSGs): Se utilizan en economizadores o secciones de evaporadores para recuperar el calor del escape de las turbinas de gas.

Precalentadores de aire: Se utilizan gases de combustión calientes para calentar el aire de combustión de la caldera.

Calderas de tubo con aletas: Se utilizan para generar los tubos dentro de la caldera.

Calentadores/enfriadores de gas de proceso: Se utilizan en las industrias petroquímica y de refinación.

Calentadores de aceite térmico: utilizar aceite térmico como fluido del lado del tubo para calentar el aire u otros gases.

Economizadores de escape para motores diesel.

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!