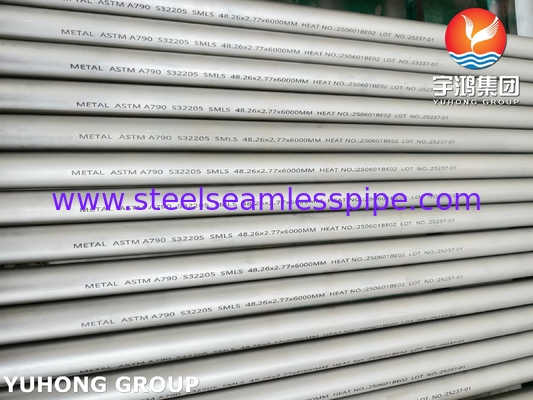

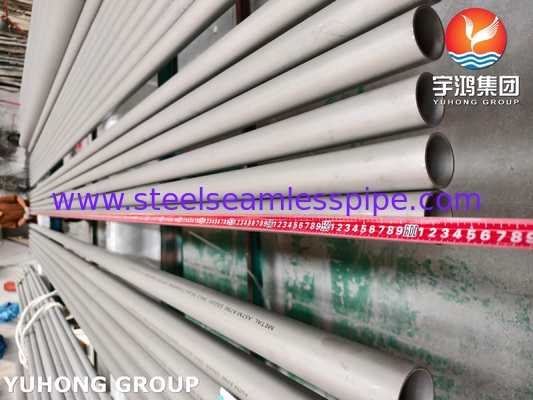

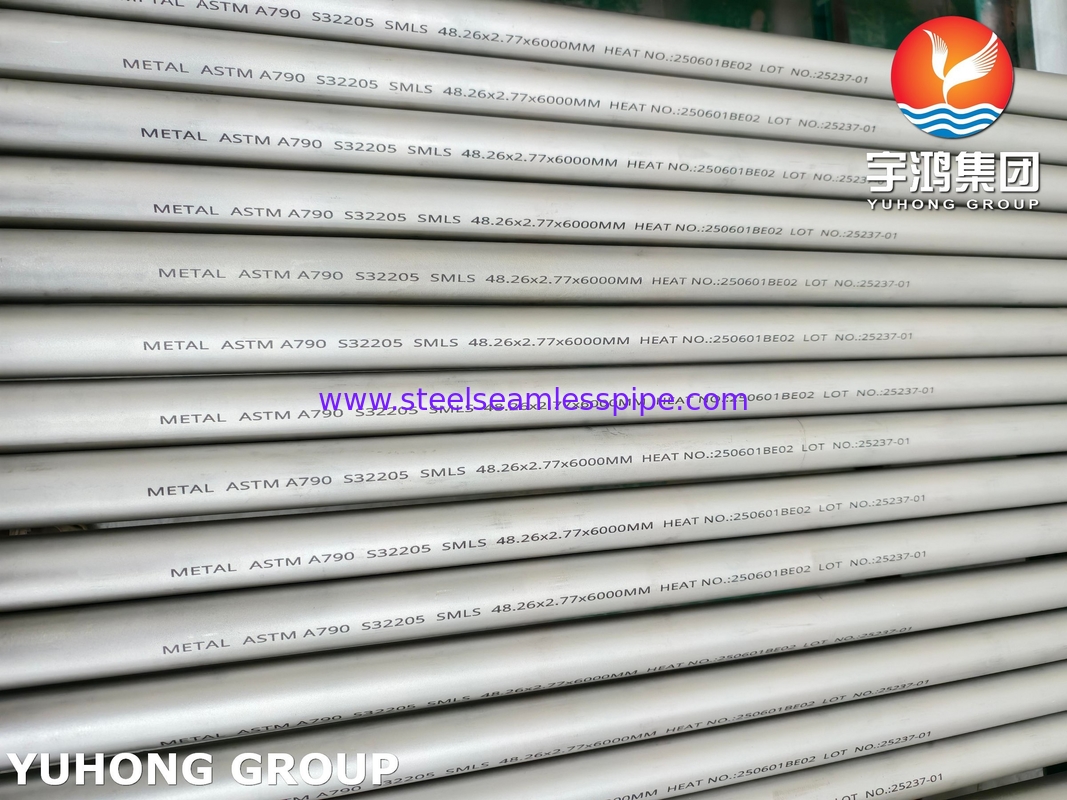

Tubo de acero inoxidable dúplex sin costura ASTM A790 S32205 de alta resistencia y resistente a la corrosión para aplicaciones en alta mar

YUHONG GROUPes un fabricante especializado en productos de acero inoxidable dúplex de alto rendimiento, con más de 30 años de experiencia en el servicio a las industrias energética y química a nivel mundial. Nuestros tubos de acero inoxidable dúplex sin costura ASTM A790 S32205 combinan una resistencia superior a la corrosión con una resistencia mecánica excepcional para las aplicaciones más exigentes.

Requisitos de tratamiento térmico para UNS S32205

| Parámetro |

Requisito |

| Designación UNS |

S32205 |

| Tipo |

2205 |

| Rango de temperatura |

1870–2010 °F [1020–1100 °C] |

| Método de enfriamiento |

Enfriamiento rápido en agua o por otros medios |

Composición química de UNS S32205

| Elemento |

Requisito (%) |

Notas |

| Carbono (C) |

≤0.030 |

Controla la formación de carburos |

| Manganeso (Mn) |

≤2.00 |

Mejora la conformabilidad en caliente |

| Fósforo (P) |

≤0.030 |

Minimiza la fragilidad |

| Azufre (S) |

≤0.030 |

Mejora la maquinabilidad |

| Silicio (Si) |

≤1.00 |

Desoxidante y potenciador de la resistencia |

| Níquel (Ni) |

4.5-6.5 |

Estabilizador de austenita |

| Cromo (Cr) |

22.0-23.0 |

Resistencia primaria a la corrosión |

| Molibdeno (Mo) |

3.0-3.5 |

Potenciador de la resistencia a la picadura |

| Nitrógeno (N) |

0.14-0.20 |

Resistencia y resistencia a la corrosión |

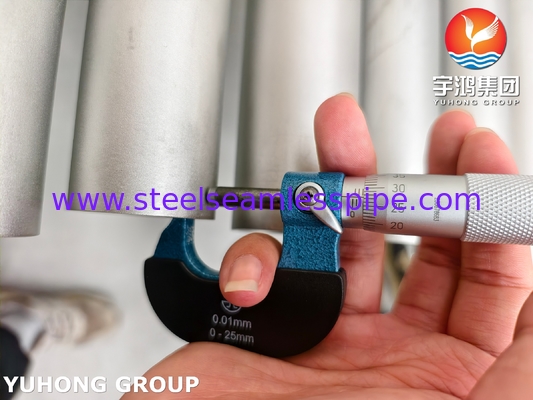

Requisitos de tracción y dureza para UNS S32205

| Propiedad |

Requisito |

Unidad |

| Designación UNS |

S32205 |

- |

| Tipo |

2205 |

- |

| Resistencia a la tracción, mín. |

95 [655] |

ksi [MPa] |

| Límite elástico, mín. |

65 [450] |

ksi [MPa] |

| Alargamiento en 2 pulg. o 50 mm, mín. |

25 |

% |

| Dureza, máx. (HBW) |

290 |

HBW |

| Dureza, máx. (HRC) |

30 |

HRC |

Ventajas clave de la aplicación del tubo de acero inoxidable dúplex sin costura ASTM A790 S32205

1. Resistencia mecánica superior para estructuras en alta mar

Resistencia a la fluencia mínima de 450 MPa (65 ksi) resiste cargas extremas de olas oceánicas y operaciones de perforación de alta presión

El alargamiento mínimo del 25% proporciona una ductilidad crítica para absorber las tensiones dinámicas en tuberías submarinas

2. Resistencia a la corrosión inigualable en entornos marinos

PREN ≥ 35 (fórmula Cr+3.3Mo+16N) previene la corrosión por picaduras/grietas en agua de mar rica en cloruro

Resiste el agrietamiento por corrosión bajo tensión (SCC) bajo tensión en la zona de salpicaduras y en condiciones sumergidas

3. Fiabilidad a largo plazo en aplicaciones críticas

Vida útil de más de 50 años en plataformas petrolíferas del Mar del Norte (casos documentados)

Reducción de los costes de mantenimiento de hasta el 60% en comparación con los sistemas 316L gracias a la eliminación de la necesidad de protección catódica

4. Mejoras en la seguridad operativa

Resistencia inherente al fuego mantiene la integridad estructural a altas temperaturas (cumplimiento de la PED)

Lixiviación de toxicidad cero garantiza la compatibilidad con la refrigeración por agua de mar para el procesamiento de GNL

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!